Documentation of the manufacturing process

During biologics development, including upscaling and changes to the manufacturing process, you must demonstrate clearance of process-related impurities from the product. Even in trace amounts, residual impurities, such as Host Cell Proteins (HCPs), can affect product quality, efficacy, and safety. HCPs qualify as a critical quality attribute (CQA) in biologics production – and authorities demand that you monitor them closely.

Mass spectrometry (LC-MS) analysis provides detailed documentation of HCP levels across process samples, and the resulting data provides a valuable tool for designing and evaluating HCP purification strategies. Mass spectrometry information about each HCP identity and quantity enables data-driven removal rather than trial and error experiments. E.g., you can make efficient removal steps for the individual HCP based on attributes like pI and molecular weight.

With MS data, you have solid documentation of removing problematic HCPs and documenting their clearance and control strategy for regulatory license applications.

Uses for LC-MS in process optimization

Troubleshooting & bridging studies

Identify and quantify HCPs and compare different downstream purification strategies for HCP clearance

Comparability testing

Monitor HCP levels during process changes, scale-up, and tech-transfer batches between CMOs

Process Performance Qualification (PPQ) analysis

Demonstrate the consistent clearance of HCPs across multiple GMP PPQ runs

Downstream development is often a matter of trying different purification steps and evaluating the effect of each. Matrix experiments take time, and the success rate may depend on complex matrix experiments or pure luck. Analysis using a standard ELISA only provides a single number representing an estimate for the total HCP amount and does not provide details of the individual amounts.

On the contrary, mass spectrometry analysis provides each protein's identity, quantity, and attributes. Based on the data, you can evaluate the efficiency of current removal steps or design new steps targeting specific HCPs. The method produces highly reproducible data for quantifying proteins, which makes it possible to follow specific residuals down to 0.1 ppm throughout the process. You may use the resulting data for intelligent process development.

MS data can also help increase the yield of the Drug Substance (in some cases 10-20%) by optimization of purification procedures (columns, pH, gradients, fraction-collection), thereby bringing down the cost of produced material (COGS) while monitoring HCPs to ensure that process changes do not increase the content of critical HCPs.

During process development, pre-clinical, and clinical phases, drug substance (DS) batches must be continuously compared (e.g., after scaling up manufacturing, transferring to a new site, or changing CMO), as inadvertent process changes may affect residual enzymes in the final drug substance. Failure to continuously monitor the residual protein profile risks may cause regulatory authority demands for more data in late-stage phases, sudden drops in product yield, unexplainable peaks in HPLC analyses, or particles in the drug product (DP) as a sign of decreased product stability.

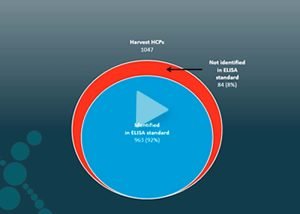

You may already have a custom ELISA developed for your process but then decide to shift CMOs or re-design the purification process. Such changes may affect the ELISA's performance or coverage since the HCP profile may have changed. Often, this results in 1-2 years for developing a new set of anti-HCP antibodies and validating the assay.

Instead, you could consider using LC-MS as an orthogonal method to support your strategy. The current ELISA might still be fit-for-purpose if you can document the changes in the process and ELISA coverage. The method can be used for detailed characterization of the ELISA reagents and to evaluate the coverage of individual HCPs before and after process changes.

We can also set up an MS assay to quantify HCP levels within weeks. Thereby, you save valuable project time and costs. And in case your HCP ELISA fails, the MS assay may even be validated according to ICH guidelines and used for GMP release testing.

Process performance qualification (PPQ) is essential to process validation during or after clinical phase III manufacturing. With the PPQ runs, you must show that your process can consistently deliver a quality product and document that the HCP level in the end product is consistent. As authorities increasingly ask for detailed data by orthogonal methods to ELISA, i.e., MS, why not include detailed data on individual HCPs clearance across the three PPQ runs?

For each step in the purification process, from the early harvest sample through the different purification steps to the pure drug substance, mass spectrometry provides the quantity of each HCP and shows how they are cleared. Comparing the HCP clearance across PPQ runs gives the complete picture and control of process consistency. Furthermore, the data can form part of regulatory documentation in the Biologics License Application (BLA) for the regulatory agency.

On demand webinar

Q&A with CMC executive Bryant McLaughlin

Bryant McLaughlin is an industry CMC expert with 15 years of experience in process optimization and IND documentation. Get his input on your concerns and queries on the power of MS-based host cell protein analysis:

- Navigate FDA guidelines confidently: Learn about Bryant's experience with the FDA's - and EMA's - stance on Mass Spectrometry (MS)-based HCP analysis.

- Learn from real-world experience: Discover how Bryant has utilized MS-based HCP analysis to overcome challenges.

- Explore the comparative value of MS-based analysis: Delve into how MS-based HCP analysis complements traditional methods like ELISAs.

Typical project process

You typically work with

these experts:

Project scope

We like to start with an online meeting to learn more about your project. Based on your needs, you will receive a draft proposal outlining the suggested analyses and expected timeframe.

Samples

After signing the final project proposal, we will contact you for details about your samples. We will inform you of an estimated report delivery date as soon as we receive your samples.

Execution

A project leader will oversee the project and send you status updates by email at regular intervals.

The analysis varies according to the project but typically includes:

- An optimized sample preparation developed explicitly for HCP samples.

- Analysis using a robust microflow HPLC and SWATH® MS/MS system to ensure high reproducibility.

- A database for protein identification specifically for your expression system and drug substance.

- Spike-in of internal standard proteins (0-2000 ppm), enabling quantification linearity even to low ppm levels.

Results

You will receive the report by email. As standard, the analysis report includes:

- Objectives, description of analytical procedure, results, and conclusions.

- List of the total HCPs in the sample.

- List of individual HCPs and their quantities.

- Evaluation of HCPs of potential concern.

- Selected raw data, e.g., excel sheets. You may request additional raw data if needed.

Follow up

Upon completion of the project, your team is invited to review the results at an online meeting.

Curious to know more?

Whatever challenge or question you may have, we are here to help you solve it. One of our protein analysis experts will discuss the best analysis approach or method for your minimizing HCP levels in your project by email or online meeting – without obligation.

Client stories

Article: Is mass spectrometry the future of impurity analysis?

Video: What is causing polysorbate degradation?

Video: Can your CDMO tackle Host Cell Proteins?

Video: Mock and harvest HCP comparison

Analysis of individual human residual proteins

Video: Orthogonal HCPs of mAb product

Video: HCP purification optimization from harvest to final DS

Video: Comparison of HCP removal strategies

Purified mAb with difficult-to-remove HCP impurity (ubiquitin)

Webinar: Data-driven process development using HCP analysis by LC-MS

White paper: HCP analysis of downstream process samples by LC-MS

Documenting product quality and process consistency

Orthogonal HCP analysis for vaccine development

Benefits of applying LC-MS in HCP process optimization

Early detection of HCPs of concern

Identify and quantify

process-related

impurities for

risk assessment

Data-driven process optimization

Compare downstream purification strategies

or create one based on HCP attributes

Faster process development

Evaluate if a

commercial

ELISA provides

sufficient coverage

Monitor process Scale-Up

Monitor HCP levels

during scale-up and

tech-transfer

between CMOs

Document Process Performance (PPQ)

Qualify and document production robustness,

consistency, and replicability

Benefits of applying LC-MS in process optimization

Early detection of HCPs of concern

Identify and quantify

process-related

impurities for

risk assessment

Data-driven purification optimization

Compare downstream purification strategies

or create one based on HCP attributes

Faster process development

Evaluate if a

commercial

ELISA provides

sufficient coverage

Monitor process Scale-Up

Monitor HCP levels during scale-up and

tech-transfer

between CMOs

Process Performance Qualification (PPQ)

Document production robustness,

consistency, and replicability

What clients say

Knowledge center

Why use intact standards to normalize MS data when quantifying HCPs instead of heavy-labeled peptides?

Intact proteins added to the sample undergo the same treatment as the sample proteins. The denaturing conditions, digest conditions, and matrix effects are the same for all proteins in the mix, and we can use the added proteins as trustworthy internal calibration standards.

Heavy-labeled peptides are not affected by the sample preparation in the same way and do not account for the effects of the treatment on the sample proteins. For this reason, heavy-labeled peptides are not our preferred choice.

Is it possible to follow the clearance of a specific HCP in the downstream process?

Analyzing a range of in-process samples using MS makes it possible to compare the sample's ppm levels of an individual HCP through purification steps. The data enables your process development team to adjust the manufacturing to remove specific HCPs from the product entirely.

Research article:

Videos:

- Analysis of gene therapies

- Analysis of residual protein in viral products

- Evaluating purification strategies

- When no commercial ELISA kit fits your expression system

- Analysis of bacteriophage product

- Residual biocatalysis in API

- Non-dilutional linearity of ELISA: Hitchhiker HCPs

- Optimized analysis of peptides for clinical trials

Poster:

Cases:

- Analysis of individual human residual proteins using an orthogonal method

- Documenting product quality & process consistency by analysis of residuals

- Orthogonal HCP analysis for mAbs

White papers:

- Protocol: Qualification of Host Cell Protein Assay using Mass Spectrometry

- HCP analysis of downstream process samples by Mass Spectrometry

Online articles:

Talk to us

Whatever protein-related challenge or question you may have, we would love to help. Our experts can help you decide on the best analytical approach for your project by email or online meeting - providing advice without obligation.